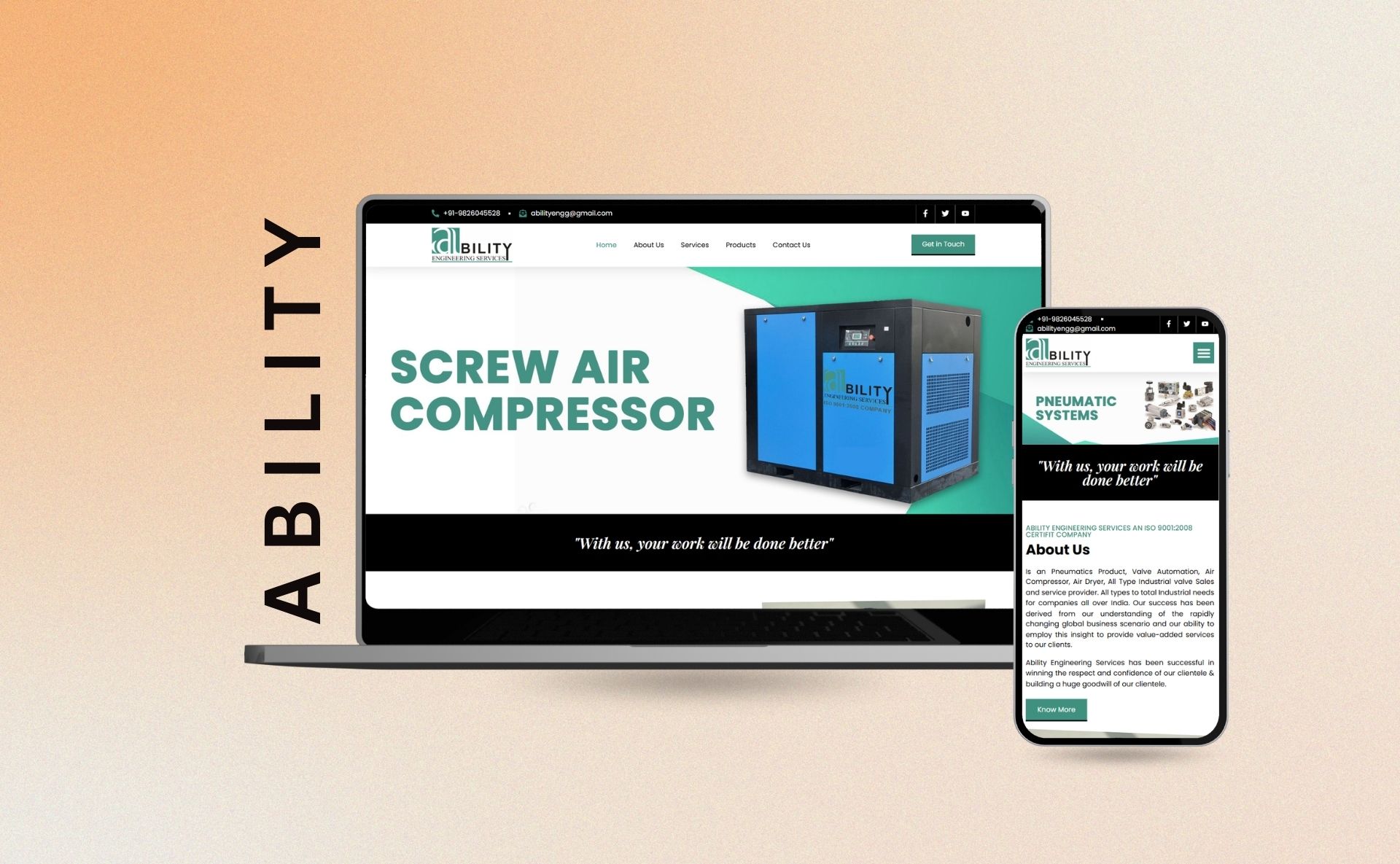

- The Story

Founded with a vision by Mr. Kaleem Shamsi in 1986, Ability Engineering started its journey as Shamsi Engineering Works to address the rising industrial demand in Central India. As the company expanded its services and capabilities, it rebranded in 2010 to Ability Engineering Services. Since then, it has emerged as a trusted name, delivering precision-driven pneumatic systems, valve automation, air technologies, and complete industrial solutions across India.

What makes Ability Engineering stand out is its ability to blend innovation with real-world functionality. Rather than offering off-the-shelf systems, the team specializes in custom-built pneumatic and automation solutions tailored to each client’s specific operational setup. This flexibility has earned them the trust of leading manufacturers, especially in sectors where performance, reliability, and speed are non-negotiable.

Furthermore, Ability Engineering brings decades of hands-on experience to every project. Their client-first approach ensures seamless collaboration-from initial consultation through installation and long-term support. As industries move toward smarter infrastructure, the company continues to deliver scalable pneumatic technologies that meet current demands while preparing for the future.

Challenges Faced During Development

During a critical project, Ability Engineering was tasked with designing a fully customized pneumatic and valve automation system compatible with legacy infrastructure. The goal was clear, but the constraints were many-limited physical space, non-standard components, and extremely tight deadlines. To overcome these, the team had to innovate rapidly, sourcing hard-to-find materials and adapting designs on the fly.

Moreover, coordinating real-time logistics while maintaining safety and efficiency added another layer of complexity. However, thanks to its strong technical foundation and agile processes, Ability Engineering not only met client expectations but exceeded them. The success reaffirmed its commitment to delivering flexible, future-ready pneumatic solutions under pressure.

The existing infrastructure lacked compatibility with modern valve and pneumatic systems, requiring tailored designs and fittings.

The available installation area was tight and irregular, demanding compact engineering without compromising performance.

Urgent deployment needs and global sourcing delays created pressure on fabrication and delivery timelines.